Report out on new nano-catalyst for recovery of viscous oil

Scientists from the Institute of Geology and Petroleum Technologies of Kazan Federal University have solved the problem of stabilizing catalysts in water, significantly increasing economic efficiency. The development is planned to be applied at the Ashalchi field in Tatarstan.

Today, unconventional oil recovery requires technologies characterized by high efficiency in terms of both productivity and minimal environmental impact. Such requirements are met by knowledge-intensive technologies that utilize the latest achievements of fundamental sciences. For example, this applies to the creation and application of oil-refining catalysts.

The catalyst must be effective, but at the same time cheap enough. Particles of nanosized catalyst with a given structure and composition effectively break the largest hydrocarbon molecules into parts, and special hydrogen donors neutralize these fragments, which leads to an irreversible decrease in the viscosity of the oil composition, increasing the proportion of light components.

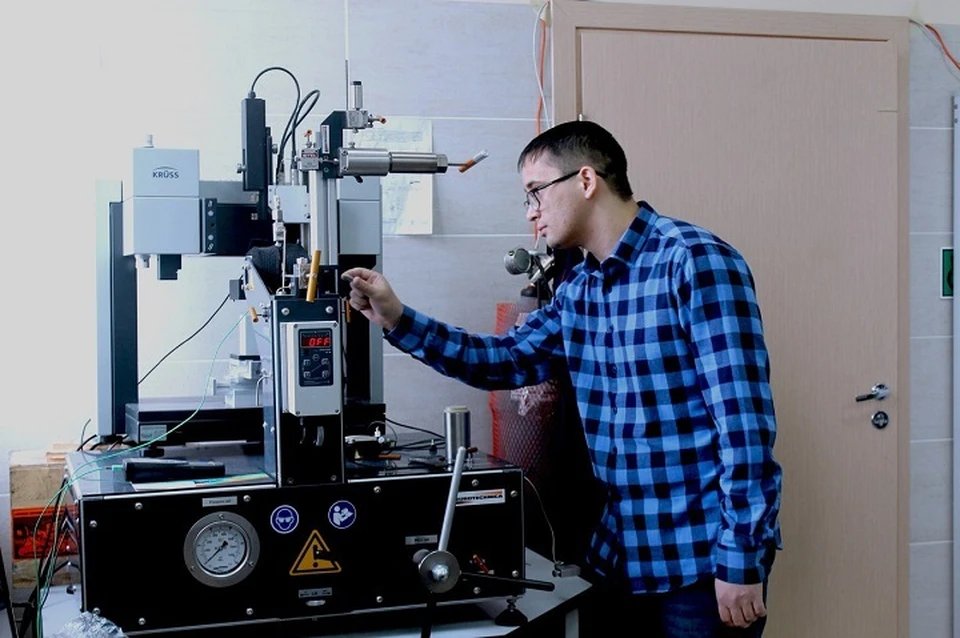

Laboratory tests of hydroconversion processes of heavy hydrocarbons using nanoscale catalysts developed in the laboratories allowed to identify the most optimal catalysts. In 2023, the Center for Liquid Hydrocarbons patented the technology of obtaining nanoscale catalyst on the basis of mixed iron oxide for intensification of heavy hydrocarbon production.

Thus, for oil refining at Ashalchi field at temperatures from 200 to 300 degrees Celsius, the most effective choice is the 1% aqueous suspension of magnetite with a small admixture of hydrogen donor and stabilizer.

The advantage of the new catalyst is the simplicity of synthesis, the low cost of the components and high efficiency in transforming the composition and structure of highly viscous oil.

“It is suspended and stabilized in water, so it is cheaper than oil-soluble catalysts,” explains Senior Research Associate Irek Mukhamatdinov.

The new series of reagents obtained by the method may become a promising material for creating new types of catalysts and be used for intensification of heavy and high-viscosity oil production.